Views: 40 Author: Site Editor Publish Time: 2023-04-18 Origin: Site

Are you in search of an accurate temperature sensor that can be used in various applications? The Negative Temperature Coefficient (NTC) sensors are an excellent option to consider. NTC thermistors are thermally sensitive resistors made from metal oxides, which decrease their resistance as temperature increases. These sensors are widely used in different fields, including automotive, medical, aerospace, and many others. This article will explore NTC sensor types and guide you on how to choose the right one for your application.

An NTC sensor is a type of temperature sensor that exhibits a negative temperature coefficient. In other words, its resistance decreases as temperature increases. These sensors are made from metal oxides and are designed to measure temperatures accurately in a variety of applications.

NTC sensors work based on the principle that as the temperature of the thermistor increases, its resistance decreases. The sensing element of an NTC sensor consists of a ceramic or polymer material that is mixed with metal oxides like manganese, nickel, cobalt, and copper. The amount of these oxides determines the resistance-temperature relationship of the thermistor.

NTC sensors offer high sensitivity to temperature changes.

They are low cost and widely available.

NTC sensors have a small size and can be easily integrated into systems.

They have a wide temperature range.

NTC sensors have good linearity and stability.

NTC sensors have a nonlinear resistance-temperature relationship, which can make calibration challenging.

They have a limited temperature range.

NTC sensors may require compensation for self-heating effects.

They are sensitive to temperature gradients and may produce errors in non-uniform temperature fields.

NTC Thermisor 52

NTC Thermisor MF51

NTC Thermisor MF58

Chip thermistors are small NTC sensors that are used in electronic circuits. They are available in a wide range of sizes and shapes and can be used for temperature measurement or temperature compensation.

Glass encapsulated thermistors are hermetically sealed NTC sensors that can be used in harsh environments. They are resistant to moisture, chemicals, and mechanical stress.

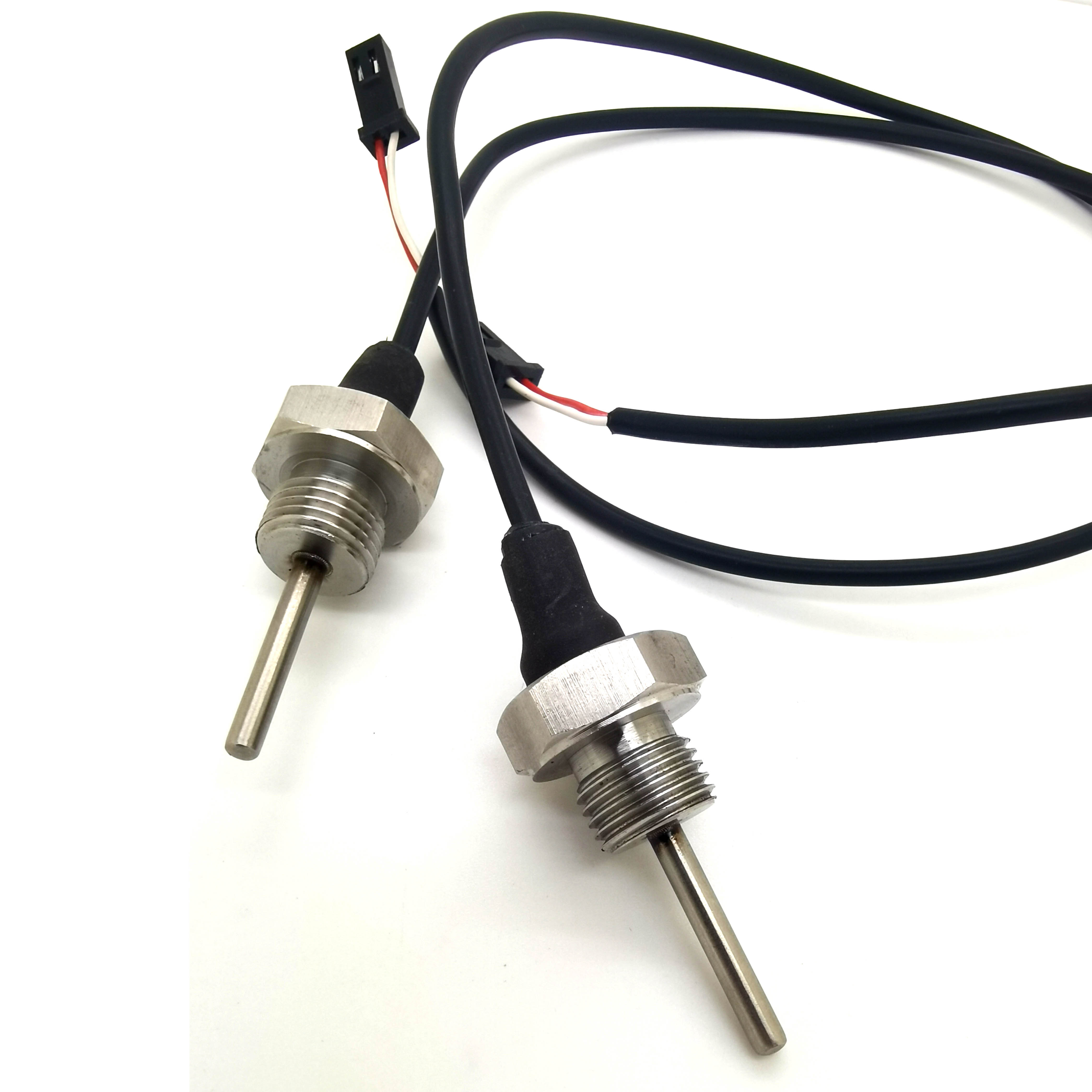

Probe thermistors are NTC sensors that are designed to be inserted into liquids, gases, or solids to measure temperature. They can be used in applications such as food processing, HVAC, and medical equipment.

Surface mount thermistors are NTC sensors that can be mounted directly onto printed circuit boards (PCBs). They are used in various electronic applications and are available in different sizes and shapes.

Radial leaded thermistors are NTC sensors that are designed for through-hole mounting onto PCBs. They are commonly used in applications such as temperature control systems, power supplies, and lighting.

Ring lug thermistors are NTC sensors that have a ring-shaped lug for easy installation. They are typically used in heating, ventilation, and air conditioning (HVAC) systems.

When selecting an NTC sensor, there are several factors to consider, including:

The temperature range of the NTC sensor should match the temperature range of the application. NTC sensors are available in a wide range of temperature ratings, from -50°C to 300°C or higher.

The resistance value of the NTC sensor should be selected based on the voltage or current that will be used to measure the temperature. It is also important to ensure that the resistance value of the NTC sensor is compatible with the measurement circuitry.

The accuracy of the NTC sensor is an important factor, particularly in applications that require high precision temperature measurements. The accuracy of the NTC sensor can be affected by factors such as temperature gradients and self-heating effects.

The stability of the NTC sensor is also critical in applications that require consistent and reliable temperature measurements over time. Factors such as aging and environmental factors can affect the stability of NTC sensors.

The response time of the NTC sensor is the time it takes to reach 63.2% of the final temperature after a step change in temperature. The response time of the NTC sensor can vary depending on its design and size.

NTC sensors are used in various applications, including:

NTC sensors are commonly used in automotive applications to measure the temperature of engine coolant, intake air, and other fluids.

NTC sensors are used in medical equipment, such as patient monitors and thermometers.

NTC sensors are used in aerospace applications to measure the temperature of critical components such as engines, turbines, and heat exchangers.

NTC sensors are used in various consumer electronic products, such as smartphones, laptops, and gaming consoles.

NTC sensors are used in HVAC systems to measure the temperature of air, water, and other fluids.

NTC sensors can be installed in various ways depending on the application. For example, probe thermistors can be inserted into liquids or solids, while surface mount thermistors can be mounted directly onto PCBs. It is important to ensure that the NTC sensor is installed correctly and securely to ensure accurate temperature measurements.

NTC sensors require minimal maintenance. However, it is important to ensure that the sensor is not subjected to mechanical stress, moisture, or other environmental factors that can affect its performance. It is also important to periodically check the calibration of the sensor to ensure accurate temperature measurements.

In conclusion, NTC sensors are an excellent option for accurate temperature measurement in various applications. There are different types of NTC sensors available, each with its advantages and disadvantages. When selecting an NTC sensor, it is essential to consider factors such as temperature range, resistance value, accuracy, stability, and response time. Proper installation and maintenance of the sensor can help ensure accurate temperature measurements over time. By understanding the different types of NTC sensors and their applications, you can select the right sensor for your specific needs.